The Threat Of Counterfeit Components To Electronic Supply Chains

Electronic equipment manufacturers and their customers must be cautious about counterfeit electronic components. They need to be especially vigilant about their supply chain as a majority of counterfeit cases reported are associated with purchases through independent distributors. As many components needed to support and produce electronics are no longer in current production, independent distributors are often used to fill this gap. It has now become necessary for all distributors of electronic components and manufacturers of electronic equipment to inspect incoming electronic components for authenticity.

The manufacture of counterfeit electric, electromechanical and electronic (EEE) parts is not a new problem for the industry, but sadly, it is a problem that continues to cost brands billions of dollars annually, jeopardizes national security initiatives, and harms the individuals buying non-authentic products. According to the Alliance for Gray Market and Counterfeit Abatement, it is estimated that legitimate electronics companies miss out on about $100 billion of global revenue every year because of counterfeiting. Statistics by the Semiconductor Industry Association (SIA) reveal that the counterfeiting of electronic parts in the US, cost the computer chip industry more than $7.5 billion in revenue annually, translating into 11,000 lost jobs. Since counterfeit parts often have inferior quality and different specifications, they may represent a hazard if incorporated into mission critical systems such as military equipment, aircraft navigation, life support, or space vehicles. The financial repercussions of counterfeit components reach far beyond the cost of merely replacing the items. For example, in certain higher-end electronic systems, a component worth $2 can cost as much as $20 to replace if it is found to be a fake after it is mounted on a circuit board.

Problems

- Part brokers: When the demand for replacement products grows higher, the price of such parts rises, providing counterfeiters’ quick opportunities for profit. Replacement of obsolete products often leads to purchases from less reliable sources such as part brokers and online exchange services instead of franchised or independent distributors. In cases of brokers and online exchange services, the actual sellers are often unidentified.

- Shift of manufacturing: To certain countries in Asia where supply chains are convoluted, and intellectual property laws are not strictly enforced.

- Online marketplaces: The rise of the Internet as a marketplace, allowing buyers and sellers to quickly trade without ever meeting in person. Middlemen in the supply chain routinely discard or re-sell electronic components that fail inspection tests or do not meet specs. These parts are useful assets for counterfeiters.

- Counterfeiters’ technology: The growing sophistication of technology has enabled manufacturing of cheaper and more convincing fakes. A variety of procedures, including acid washes, surface sanding, river washes and exposure to open flames are used to conceal the true origin. Following concealment, these components are relabeled as military-grade using digital printing techniques and lasers, before being packaged and offered to brokers across the globe.

- Global e-waste handling: Few countries continue to export their hazardous electronic waste to the developing world, where ‘e-waste recycling’ has become a way of life. This e-waste provides valuable raw materials for counterfeiters and criminal gangs.

- Weak brand protection: Generic labels employing legacy technologies (e.g. legacy holograms) with no clear validating visual cues or striking elements are easy to counterfeit. To fight fakes, the electronics component industry is in need for enhanced security labels backed by technology that is extremely difficult to replicate and easy to authenticate. Electron Beam Lithography holograms and nanotechnology solutions coupled with Track & Trace capabilities are superior offerings to protect brands.

Effective approaches to avoiding counterfeits

1. Always purchase components directly from the original manufacturer, or from an authorized distributor. Electronic parts sourced through other channels are often misrepresented as to their origins or quality. Visually examine all labels, packaging, and parts. Compare these elements to parts of a genuine model from the original component manufacturer (OCM) and look for any differences between the two.

- Incorrect part codes different from OCMs

- Spelling errors and inaccurate information on labels

- Invalid date codes (i.e., too far in the past or into the future)

- Missing elements like humidity indication cards, dry packs

- Poorly imitated logos, font or branding elements that do not match the OCM

- A stated country of origin that does not align with the printed country code

- Unclear or low resolution holograms

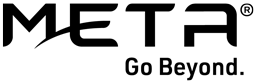

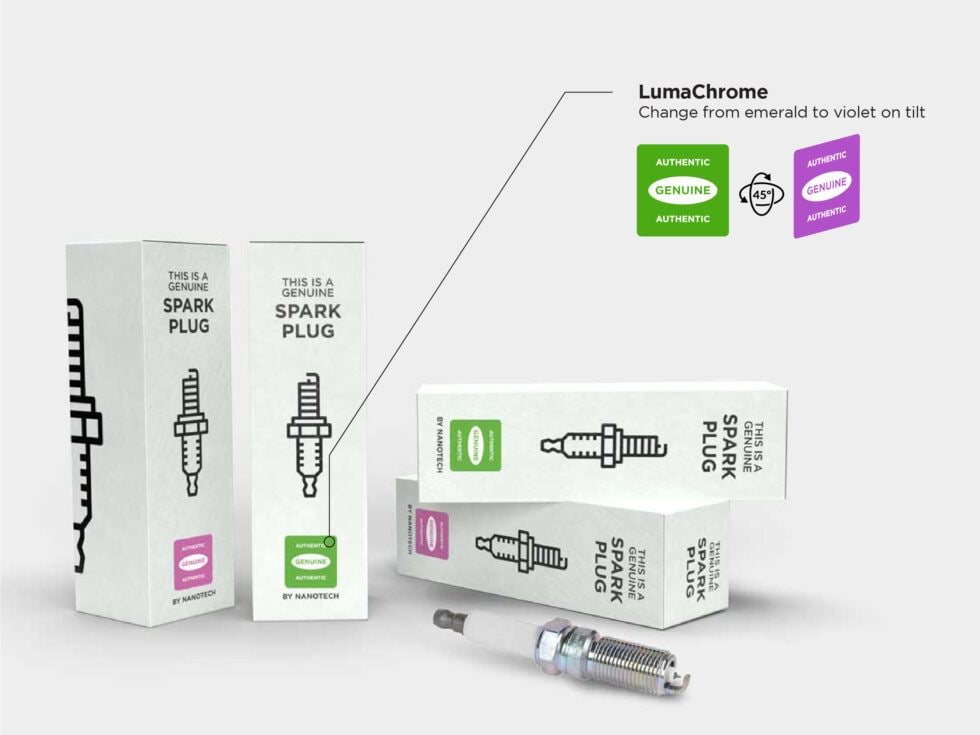

2. Employ comprehensive brand protection solutions that work together to protect supply chain integrity and confirm product authenticity. Overt authentication features included on Nanotech’s LiveLogo™, LivePortrait™, and LumaChrome™ nano-optic security labels can be combined with an extensive range of identification markers that include QR codes, serialization, production data, microtext, covert and forensic elements, and a suite of other unique identifiers. Authentication features include:

- Striking colour-shifting film, product or portrait imagery supported by the ability to embed visible and/or hidden security elements.

- Unique effects such as “On-Off” and “On-Invisible” backed by next-gen nano-optic technology offer quick authentication.

- Compatible with mobile and web-based scanning tools for authentication of the security labels with the manufacturer`s choice of identifiers.

- Multi-colour, 3D depth, movement, and image switches in multiple formats including stripes, PSA labels, patches that cannot be captured or duplicated with comparable quality.

Conclusion

Nanotech’s anti-counterfeit security labels can help you safeguard supply chain integrity, improve operational efficiencies, combat product diversion and grey market activity. Weather you are an OCM, Franchise Distributor, Independent Distributor or Wholesaler remember – prevention is always the first line of defense. Security labels along with a robust arsenal of inspection, identification, detection, documentation, and certification techniques minimize the risk of incorporating or shipping out a counterfeit electronic component. As many companies are learning the hard way, anti-counterfeiting plans require a relentless, multifaceted, methodical effort, active monitoring of potential trouble spots, and judicious use of novel anticounterfeiting technologies.

Sources

IEEE Transactions on Components & Packaging Technologies (Volume: 30, Issue:1)

Open Journal of Social Sciences 2013. Vol.1, No.7, 12-16: The Counterfeit Electronics Problem

https://en.wikipedia.org/wiki/Counterfeit_electronic_components

https://www.trentonsystems.com/blog/counterfeit-electronic-parts