Types Of Notch Filters And Their Applications

Notch filters have become an indispensable tool across a disparate range of fields, including astronomy, spectroscopy, microscopy, life and biomedical sciences, machine vision, and surveillance due to their distinctive optical properties.

Generally speaking, optical filters are components used to selectively transmit or reject specific optical wavelengths or wavelength ranges. Several types of optical filters exist for different applications. A longpass filter transmits wavelengths longer than a particular wavelength, while blocking all shorter ones. The opposite effect can be achieved with a shortpass filter. A bandpass filter permits wavelengths within a certain range (known as the passband) to pass and rejects those outside this range. Conversely, a notch filter rejects a particular narrow wavelength region (referred to as the stopband) within the optical spectrum, while transmitting the remainder. Broadly, notch filters can be categorized based on their mechanism of action into two major types:

- Absorptive

- Reflective

Absorptive Filters

Absorptive filters eliminate undesired wavelengths through absorption. They are typically made of optical glass or plastic uniformly impregnated or coated with dye molecules. Renowned for their low cost, simple structure, outstanding rejection efficiency, high mechanical stability, and incident-angle independence, these dye-based filters find use in various applications, extending from ultraviolet (UV) and infrared (IR) light blocking and laser safety eyewear to traffic signage and theatrical lighting. The efficacy of an absorptive filter is directly proportional to its thickness and dye content.

Despite being highly effective light blockers, absorptive filters face three intrinsic issues that restrict their employment:

- Absorptive filters generally have broad stopbands and do not have sharp transitions between maximum and minimum transmission. These constraints hinder their implementation in optical component use cases requiring steep spectral edges and minimum out-of-band intensity loss.

- The dye contained in an absorptive filter may fluoresce and consequently affect signal detection accuracy when used in fluorescence-based optics.

- An absorptive filter converts the light it absorbs into heat, which may damage the filter and its dye component and therefore irrevocably alter its spectral shape.

Reflective Filters

In contrast, a reflective filter operates by reflecting, rather than absorbing, the unwanted portion of the incoming light. Such selective manipulation of light is accomplished through the exploitation of optical interference. For this reason, reflective filters are also known as interference filters.

Depending on their phase relation, light waves can interfere with each other either constructively or destructively, that is, the amplitude of the combined wave will be greater or smaller than the amplitude of any of the contributing waves, respectively. Constructive and destructive interference effects collectively produce an interference pattern composed of alternating bright and dark fringes. In principle, an interference filter comprises a structure with a refractive-index profile featuring alternating high and low values. Incident light is partially reflected and refracted at all these transitions, leading to constructive and destructive interference of all the waves. Hence, tailoring the refractive-index profile enables control over the spectral profile of transmission and reflection. Two approaches are primarily used to fabricate interference filters:

- Dielectric material deposition

- Volume holographic gratings (VHGs)

Dielectric Thin-Film Filters

Dielectric filters dominate the current market of interference filters. They are produced by coating a substrate with a stack of alternating thin (mostly submicron) layers of two transparent dielectric materials with different refractive index values using a deposition process such as reactive sputtering. Light incident on a dielectric filter is both reflected and refracted at each layer interface within the coating. Careful selection of two key layer parameters, namely, thickness and refractive index, enables the multilayer structure to induce the desired interference effect, either reflection or transmission, for the target wavelength. For a notch filter in particular, constructive interference between the reflected waves in the stopband region effectively prevents their transmission through the filter. Increasing the number of alternating layers typically increases the optical density (OD) of the filter. One prominent application of dielectric filters is in Raman spectroscopy where they are used to ensure detection of both Stokes and anti-Stokes Raman light at a high signal-to-noise ratio.

These thin-film interference filters offer three key advantages over absorptive filters:

- As they do not retain light energy, dielectric filters can withstand high-intensity light.

- The absence of dyes in dielectric filters eliminates the concern surrounding fluorescent noise when integrated into fluorescence-based instruments.

- Dielectric filters can also be computationally customized to produce a precisely defined spectral profile with a narrow and sharp stopband, making them an ideal tool for blocking specific wavelength ranges.

Conversely, unlike absorptive filters, dielectric filters are extremely sensitive to the angle of incident light. This is because the effective layer thickness experienced by light waves depends on their incident angle.

The angular specificity results in high alignment sensitivity and a variation in a filter’s spectral response to noncollimated light. As the refractive index varies with temperature and humidity, dielectric filters may not perform reliably in volatile ambient conditions. Depending on the prescribed spectral outcome, manufacturing dielectric filters may also require a laborious and costly deposition process that often involves rare-earth metals and scarce minerals.

VHG Filters

In recent years, VHG filters have gained currency as an appealing alternative to conventional dielectric solutions for discarding unwanted wavelengths. Functioning based on optical interference, VHG filters share many of the attributes of dielectric filters such as narrow stopbands. However, unlike dielectric filters, VHGs are quick to produce across large surface areas, environmentally sustainable, and readily configurable. Apart from notch filters for laser analysis applications, VHGs are also frequently used in many other areas, including augmented reality, light-emitting diode and solar applications, wavelength stabilization, pump-light injection, and dispersive pulse compression. In the case of a VHG notch filter, a similar concept to holography is used, albeit the object encoded in the hologram is effectively a mirror.

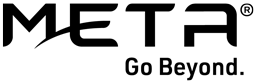

For a VHG notch filter, the interference pattern is formed by two intersecting coherent and monochromatic beams of collimated laser light. Such an interference pattern comprises a series of parallel interference (or grating) planes that will feature a periodically varying refractive index in the developed holographic material. The grating planes exist throughout the thickness (typically several microns) of the recording medium that is appreciably greater than the wavelength of the recording light. This characteristic is the reason behind the term “volume” and differentiates a VHG from a surface-relief grating with a diffraction structure (e.g., a set of grooves) present only on the surface. A grating with planes parallel to the filter surface is called a conformal grating, whereas a grating with planes in any.

other orientation relative to the filter surface is referred to as a slanted grating (Figure 1).

Based on their response to incident light, VHGs can be grouped into two categories: transmissive and reflective, the latter of which is suitable for use as notch filters.

In our next blog, we cover holoOPTIX® notch filters from Meta Materials Inc. (META®). They offer a high-performance, environmentally sustainable, and versatile alternative to conventional dielectric solutions for rejecting undesired wavelengths of light. These holographic filters can be readily customized in various characteristics, such as the target wavelength, optical density, angle of reflection, dimension, and format, to satisfy customers’ unique optical demands. Currently, holoOPTIX® notch filters are available for purchase in two configurations (a standard 25.4-mm rigid-mounted configuration (STRATA) and a unique 70-mm × 375-mm flexible configuration (FLEX)) and for three center wavelengths (CWLs) (457, 532, and 635 nm) through Edmund Optics or the META® estore. Each filter’s CWL can be readily tuned by adjusting the angle of incidence while maintaining consistency for both p- and s-polarizations, even at large angles of incidence. Custom solutions are available upon request.